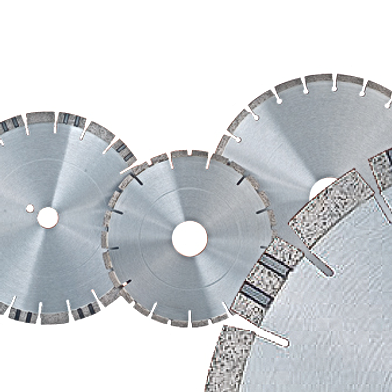

Dry Laser Welded Diamond Blade

6" (150mm)

Dry Laser-Welded Diamond Saw Blade : Advanced Technology for Dry Cutting

The Dry Laser-Welded Diamond Saw Blade showcases advanced technology for dry cutting applications. Its laser-welding technique ensures a secure and robust construction, providing confidence to operators and users alike in dry cutting conditions.

Key Features:

Overall, Diamond Blade and the Dry Laser-Welded Diamond Saw Blade offer exceptional performance and reliability, making them indispensable tools for various industries. Their high performance, precision, safety, and efficiency make them a preferred choice for professionals, ensuring exceptional cutting performance and reliability in various applications.

Item No. | Outside Diameter | Segment Dimensions (mm) | Segment Dimensions (mm) | Segment Dimensions (mm) | Arbor |

Length | Thickness | ||||

TTG2040 | 4" (105mm) | 32 | 8 | 2.2 | 7/8" - 5/8" |

TTG2045 | 4-1/2" (115mm) | 32 | 8 | 2.2 | 7/8" - 5/8" |

TTG2050 | 5" (125mm) | 32 | 8 | 2.2 | 7/8" - 5/8" |

TTG2060 | 6" (150mm) | 32 | 8 | 2.4 | 7/8" - 5/8" |

TTG2070 | 7" (180mm) | 32 | 10 | 2.4 | 7/8" - 5/8" |

TTG2080 | 8" (200mm) | 32 | 10 | 2.4 | 7/8" - 5/8" |

TTG2090 | 9" (230mm) | 32 | 10 | 2.8 | 7/8" - 5/8" |

TTG2100 | 10" (250mm) | 40 | 10 | 2.8 | 7/8" - 1" |

How to Buy

Request an Equipment Quote

Ready to buy stuff from Flexible,Request a quote now.

Buy

Browse Parts and equpments on our store

Reviews

FAQ

Q: What are the most common types of drilling method?

Here are the five common types of oil drilling techniques. 1. Cable Drilling. 2. Directional Drilling. 3. Electro-Drilling. 4. Rotary Drilling. 5. Dual-Wall Reverse- 6. Circulation Drilling.

Q: How deep can a drill rig go?

Depending on the rig type, offshore rigs are rated to drill in water depths as shallow as 80 feet to as great as 12,000 feet. The greatest water depth a jackup can drill in is 550 feet, and many newer units have a rated drilling depth of 35,000 feet.

Q: What is the process of oil exploration?

Oil and gas exploration encompasses the processes and methods involved in locating potential sites for oil and gas drilling and extraction. Early oil and gas explorers relied upon surface signs like natural oil seeps, but developments in science and technology have made oil and gas exploration more efficient.

Q: What are the positions on a rig?

Diver – Some rigs require the use of divers to maintain the underwater equipment. Driller – Heads up all operations related to the drilling equipment. Electrician – Maintains and repairs all electrical systems onboard the rig. Floorman – Provides general support to the rig's drilling operations.